Tools and Materials Required for Alternator Replacement

When undertaking a Land Rover Discovery alternator replacement, having the right tools is paramount for both safety and efficiency. Essential tools include a socket set, wrenches, and screwdrivers. These provide the grip and leverage needed for dealing with the specific bolts and connections in the vehicle. A multimeter is also recommended for ensuring the new alternator functions correctly after installation.

In terms of materials, choosing the right alternator is crucial. OEM (Original Equipment Manufacturer) parts ensure compatibility and tend to offer more reliability but are often pricier. Conversely, aftermarket alternatives might offer cost savings but can vary in quality. Be sure to cross-reference the part number to guarantee a proper fit for your vehicle.

Have you seen this : Mastering mclaren 720s: your comprehensive handbook for installing and tuning a performance data logger to unlock exceptional track insights

The importance of quality tools cannot be understated. High-quality tools not only withstand the stress of the job but also ensure precise work, reducing the risk of damaging sensitive vehicle components. Employing subpar tools can lead to complications, prolonging the replacement process and even posing safety hazards. Thus, investing in robust, reliable tools is recommended to ensure a smooth and successful alternator replacement.

Safety Precautions to Consider

Safety should always be a priority when tackling a Land Rover Discovery alternator replacement. Before beginning the process, it is crucial to disconnect the battery. This prevents the risk of electrical shocks, which can be dangerous. Give the vehicle time to cool down; the engine and its components can become extremely hot.

Personal protective equipment is essential. Always wear gloves and safety goggles to protect against potential injury. Gloves offer grip and shield from sharp parts, while goggles safeguard your eyes from debris or splashes that might occur during the replacement.

With larger vehicles like the Land Rover Discovery, be aware of specific potential hazards. The vehicle’s height and weight can pose unique risks, such as falls or muscular strain. Ensure you work on a stable, level surface and use appropriate supports or lifts to reduce strain and prevent accidents.

In summary, by observing these safety tips, you minimize risks associated with replacing alternators. Safety measures like these ensure a smoother, safer experience when dealing with complex automotive repairs. Committing to these protocols not only protects you but also contributes to an efficient and successful alternator replacement process.

Step-by-Step Instructions for Removal

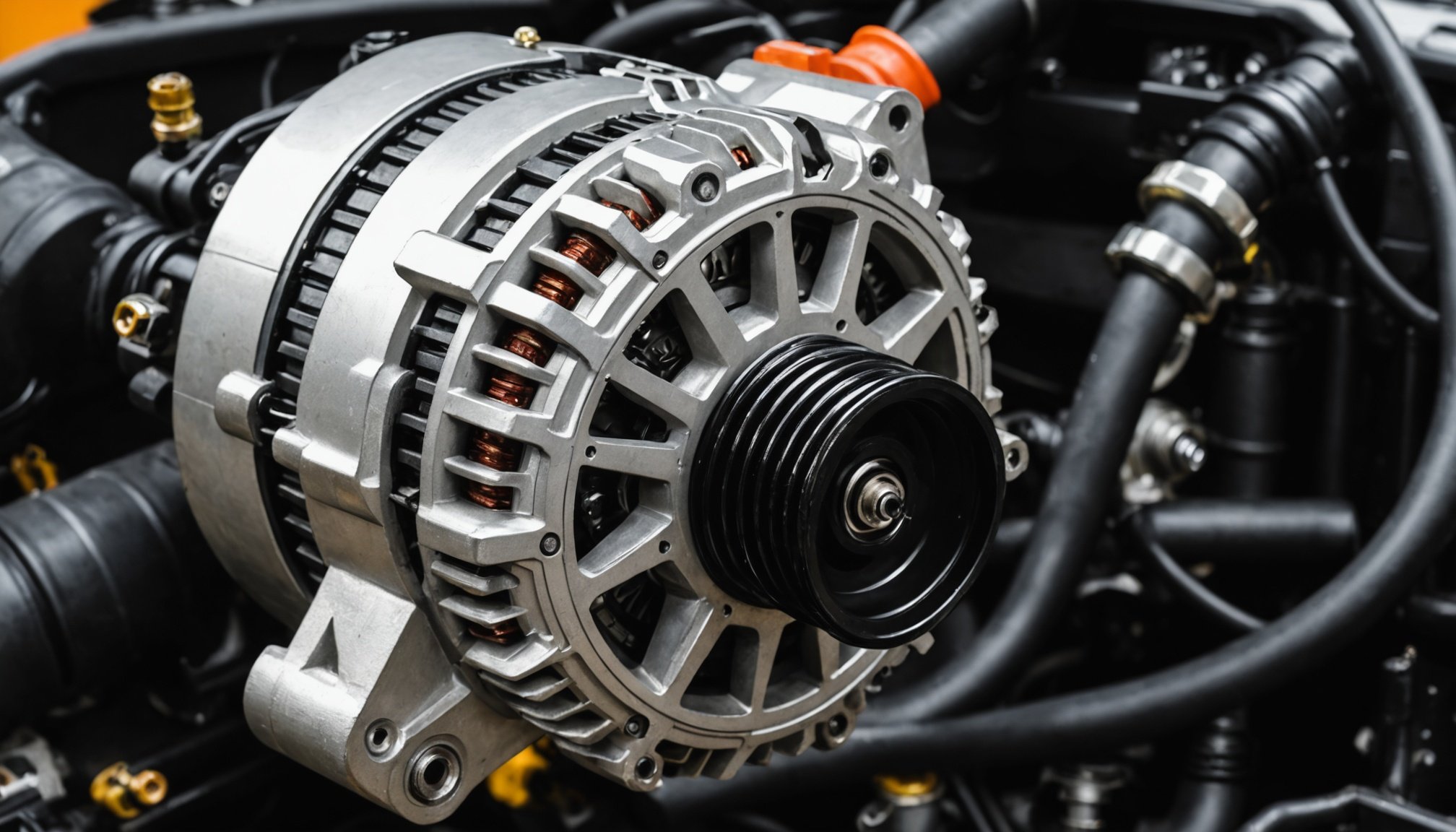

Embarking on the journey to remove your Land Rover Discovery alternator can seem complex, but detailed guidance makes it manageable. Start by ensuring safety: disconnect the battery to prevent electrical hazards. The next task is accessing the alternator. You’ll find it at the front of the engine, adjacent to the serpentine belt. Identify and remove any obstructions, like the air intake duct or engine cover, to create space.

Focus on identifying the necessary bolts and connections. You’ll usually need to remove the serpentine belt tensioner to access the alternator bolts. Use the socket set to loosen these bolts but maintain a methodical approach to avoid mixing them up during reassembly. Also, be attentive to the electrical connectors linking the alternator to the vehicle’s system—carefully disconnect these to prevent damage.

Avoiding common missteps ensures a smoother process. Keep track of all components you remove, and take photos if needed for reference during reinstallation. Organise the workspace to minimise the risk of losing bolts or tools. By following these structured steps, removing the alternator becomes a task of method rather than mystery, setting the stage for effective replacement.

Step-by-Step Instructions for Installing the New Alternator

Installing the alternator in a Land Rover Discovery involves careful attention to detail to ensure proper fit and functioning. Begin by positioning the new alternator in the correct location within the engine bay. Proper alignment is crucial; ensure that the alternator’s mounting holes line up with the engine brackets.

Next, secure the alternator by inserting and tightening the bolts. It’s best to tighten these bolts evenly to avoid stressing the component. Following this, reconnect the electrical connections. Double-check these to ensure they are snug and free from corrosion, ensuring reliable power flow.

Reinstall the serpentine belt, making sure it is tensioned correctly. A loose belt can lead to underperformance, while an overly tightened belt may damage the alternator. After everything is in place, conduct a visual check for any warning signs, like loose wires or unfastened components, before closing the hood.

Start the engine and check for any unusual noises or warning lights on the dashboard, as these could indicate improper installation. Doing this guarantees that your alternator is delivering optimum performance, and it allows proactively addressing any issues that arise immediately following installation. This helps maintain the longevity and reliability of your vehicle’s electrical system.

Maintenance Tips for Optimal Performance

Maintaining your Land Rover Discovery alternator is essential to ensure its longevity and efficiency. Regularly inspecting the alternator after installation helps identify potential issues early. Look for signs such as unusual noises or dashboard warning lights, which could indicate underlying problems.

Ensure that the alternator’s electrical connections and serpentine belt remain in good condition. Corrosion or loose connections can hinder performance. If you spot any signs of wear on the serpentine belt, replace it promptly to prevent further damage to the alternator itself.

For optimal performance, perform routine checks on the alternator. Listen for any subtle changes in sound that might suggest a developing issue. If the alternator struggles to charge efficiently, it could signal a problem with the diode or voltage regulator.

- Inspect regularly: Keep a schedule to monitor the alternator’s condition.

- Check connections: Ensure they are clean and secure.

- Monitor performance: Pay attention to any signs of malfunction.

By adhering to these best practices, the alternator can deliver consistent performance, maximizing its lifespan. Regular maintenance is a proactive approach that can prevent costly repairs, ensuring the reliability of the vehicle’s electrical system over the long term.

Troubleshooting Common Issues

Post-installation problems with a Land Rover Discovery alternator may occur, and knowing how to tackle them is vital. A frequent issue is strange noises emanating from the engine bay. If you hear a whining or grinding sound, it might indicate a misaligned alternator or worn-out bearings. Ensure the alternator is correctly secured and free of debris that might cause wear.

Dashboard warning lights, like the battery indicator, could signal a charging issue. If the alternator fails to charge the battery, first verify that all electrical connections are properly secured. Look for signs of corrosion, as they can impede the alternator’s ability to function.

Should you face an issue where the alternator does not charge, consider using a multimeter to test the battery’s voltage. Ideally, the reading should be around 13.8 to 14.2 volts with the engine running. If the voltage is significantly lower, the alternator may need further inspection or replacement.

Experiencing recurring issues might require professional diagnostics. Consulting resources like Land Rover service manuals or forums could offer additional insights. Engaging with experts can expedite resolving persistent complications, ensuring your vehicle’s electrical system performs optimally.

User Experiences and Recommendations

Experiences with Land Rover Discovery alternator replacement vary widely among users. Many Land Rover owners recommend opting for OEM alternators due to their proven reliability and compatibility. These parts often align perfectly with vehicle specifications, ensuring seamless integration and fewer unexpected issues during installation.

Conversely, users who’ve opted for aftermarket alternators often cite significant cost savings, although opinions on performance and durability differ. While some report satisfactory experiences, achieving a balance of quality and affordability, others express frustration with premature failures and compatibility issues. As such, it’s crucial to research brands and read reviews carefully when considering aftermarket options.

A recurring theme in user reviews is the importance of proper installation techniques. Many users emphasize the need for professional installation, particularly when dealing with aftermarket models, to ensure performance and longevity. Proper installation can significantly influence the alternator’s effectiveness and the vehicle’s overall electrical system.

Recommended brands frequently mentioned include Bosch and Denso for OEM parts, known for their quality and reliability. These choices often deliver more consistent outcomes post-installation. Overall, taking the time to understand user experiences can aid in making informed decisions about which alternator option best suits your needs, balancing cost, performance, and reliability.

Aftermarket vs. OEM Parts: Which to Choose?

When deciding between aftermarket and OEM alternators for your Land Rover Discovery, multiple factors come into play. Many vehicle owners grapple with this decision due to concerns about cost, compatibility, and performance.

OEM alternators are produced by the original vehicle manufacturer. They offer a guarantee of quality and compatibility, ensuring seamless integration with your vehicle. This reliability often comes with a higher price tag, but the long-term benefits, such as fewer unexpected failures, justify the expense for many.

In contrast, aftermarket alternators present an appealing option for those on a budget. These parts are typically cheaper and can offer a balance between cost and performance if chosen wisely. However, experiences with aftermarket parts can be mixed. Some users report premature failures or issues with fitting and overall performance.

User experiences significantly influence this choice. Many recommend Bosch and Denso for their durability and performance, especially in OEM formats. For those exploring aftermarket options, conducting thorough research and reading reviews on specific models can help mitigate risks. Ultimately, understanding the trade-offs between price, quality, and reliability helps in making an informed decision tailored to your vehicle’s needs.